Top 5 Reasons Your Refrigerated Display Case Isn’t Cooling Properly (and How to Fix It)

Plus some quick checks to help you troubleshoot.

If your deli, dairy, or beverage case is running warm, product quality and shrink move in the wrong direction—fast. Below are the five most common causes we see in the field, simple checks you can do today, and when it’s time to call AM Refrigeration. We sell, install, repair, and design complete supermarket refrigeration—from single cases to full low-temp systems—so you’re covered from day one to year ten.

TL;DR: Quick Checks You Can Do in 10 Minutes

1. Clear airflow: Pull product back from air discharge/return grills; remove cardboard risers.

2. Close the “air curtain”: Keep night covers closed when required; avoid fans/AC vents blowing on the front.

3. Clean the condenser coil: Brush/vacuum dust and debris (power off first).

4. Inspect door gaskets & hinges: Look for tears, gaps, or doors not self-closing.

5. Verify settings: Confirm setpoint, defrost schedule, and case controller are correct per the manufacturer.

If temps don’t improve within a few hours, call AM Refrigeration—continued warm temps risk food safety and big losses.

Reason #1: Dirty or Blocked Condenser Coils

Symptoms: Case runs constantly, still warm; cabinet or machine compartment feels hot; higher energy bills.

Why it happens: Dust, grease, and lint act like a blanket over the coil, preventing heat from leaving the refrigerant loop.

What to do:

* Disconnect power. Remove front or rear grill.

* Brush and vacuum the coil fins (no pressure washing).

* Restore proper clearance around the machine compartment.

Pro note: If cleaning helps briefly but temps drift again, you may be dealing with a failing condenser fan motor or high head pressure—time for a tech visit.

Reason #2: Airflow Problems & Product Loading

Symptoms: Product near the front warms first; fogging; uneven temps top-to-bottom.

Why it happens: Open multi-decks rely on a stable air curtain. Blocking discharge or return grills, over-stacking, or cross-drafts (ceiling fans, HVAC supply diffusers, open doors) collapse the air curtain.

What to do:

* Keep product below load lines and off the front ledge.

* Maintain 2–4 inches of clearance in front of air returns; never tape on signage that blocks vents.

* Redirect HVAC supply air away from the case.

Pro note: For persistent issues, we can add air baffles, re-balance the store HVAC near cases, or evaluate case selection for your product mix.

Reason #3: Worn Door Gaskets, Hinges, or Night Covers

Symptoms: Condensation/ice around doors; doors won’t self-close; visible tears or gaps in gaskets; higher run time.

Why it happens: Gaskets compress and tear with use; hinges drift; night covers wear out. Even a small gap pulls warm, moist store air into the case, icing the coil and warming product.

What to do:

* Close a dollar bill in the door—if it slides out easily, the seal is weak.

* Replace torn gaskets; adjust/replace hinges so doors self-close and align square.

* Repair or replace frayed night covers; keep them down during off hours.

Pro note: Replacing gaskets is a fast, high-ROI fix that lowers energy use and stabilizes temps.

Reason #4: Incorrect Setpoints, Sensors, or Defrost Schedules

Symptoms: Temps swing hot after defrost; controller shows alarms; ice build-up on the evaporator; product soft in low-temp cases.

Why it happens: A case controller setpoint that’s too high, a bad thermistor, or a defrost schedule that’s too frequent/too long can warm the case or ice the coil.

What to do:

* Verify the case setpoint and cut-in/out align with the manufacturer spec and product type.

* Check defrost—number, start times, duration, and termination. Avoid defrosting during peak traffic if possible.

* If temps shown on the controller don’t match a calibrated product simulator/thermometer, the sensor may be faulty.

Pro note: Modern EEVs (electronic expansion valves) and case controllers are precise—but only when programmed and calibrated correctly. We can tune these to your store’s load profile.

Reason #5: Refrigeration System Faults (Fans, Ice-Bound Coil, Low Charge, Compressor Issues)

Symptoms: No/weak air movement; visible ice block on the coil; short cycling; hissing/bubbling; oil stains on piping; breaker trips.

Why it happens: Failed evaporator or condenser fan motors, refrigerant leaks/low charge, restricted driers, or compressor/mechanical failures reduce capacity.

What to do (safely):

* Confirm evaporator fans spin freely with power on; if not, shut down and call a pro.

* If the coil is a block of ice, power down to prevent liquid floodback and schedule service—the root cause may be defrost or low airflow, not just “too cold.”

* Do not add refrigerant yourself. Handling refrigerants requires EPA-certified technicians.

Pro note: We leak-check, weigh in correct charge, replace failed components, and verify superheat/subcooling so the case performs like new.

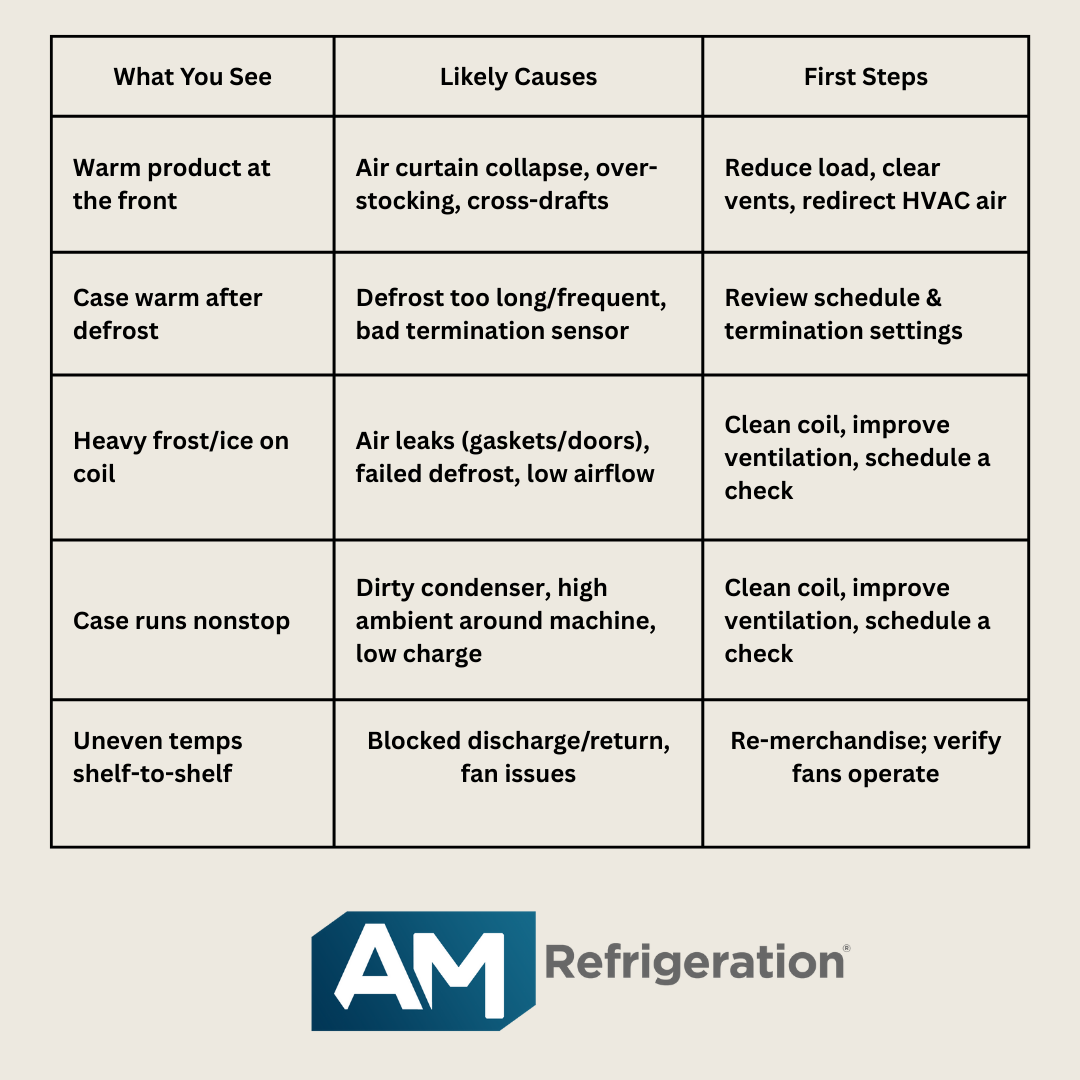

Symptom → Cause Quick Reference